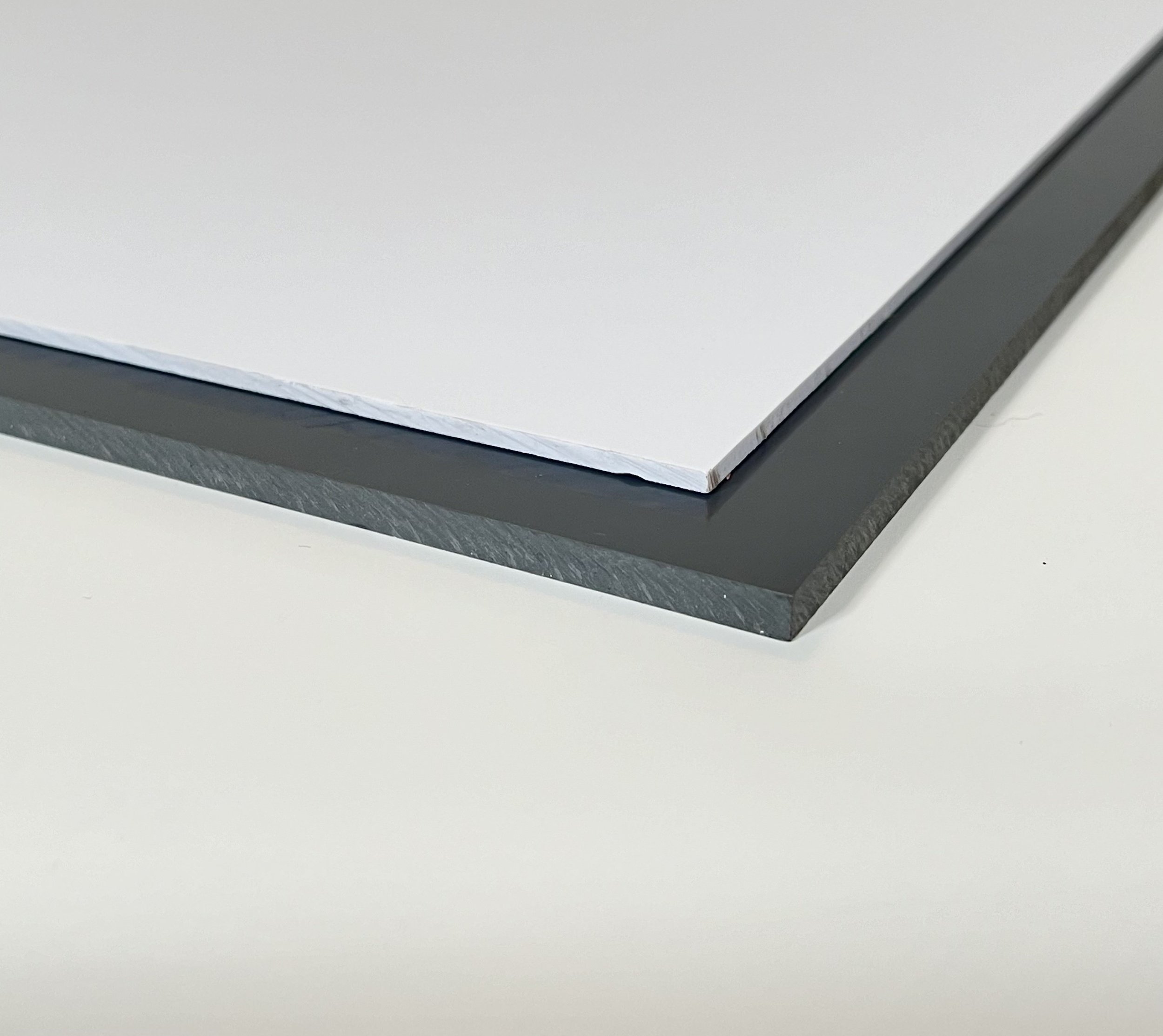

ABS Sheet

ABS is a versatile and cost effective thermoplastic created using three unique compounds. ABS is rigid, tough and impact resistant enabling effective use in a number of indoor and outdoor applications. Often recognized by its glossy surface or haircell texture, ABS possesses combination of properties making it an ideal choice in numerous industries.

ABS is exceptionally durable, has low moisture absorption, good dimensional stability, excellent chemical resistance, is very easy to fabricate, and thinner gauges can be die-cut. ABS also has a high heat tolerance which allows it to be thermoformed to shape, or sonic welded to various materials such as wood, epoxy, ceramic, and aluminum. ABS parts can also be fastened using screws, bolts, nuts, rivets, or spring steel fasteners.

ABS is a versatile and cost effective thermoplastic created using three unique compounds. ABS is rigid, tough and impact resistant enabling effective use in a number of indoor and outdoor applications. Often recognized by its glossy surface or haircell texture, ABS possesses combination of properties making it an ideal choice in numerous industries.

ABS is exceptionally durable, has low moisture absorption, good dimensional stability, excellent chemical resistance, is very easy to fabricate, and thinner gauges can be die-cut. ABS also has a high heat tolerance which allows it to be thermoformed to shape, or sonic welded to various materials such as wood, epoxy, ceramic, and aluminum. ABS parts can also be fastened using screws, bolts, nuts, rivets, or spring steel fasteners.

ABS is a versatile and cost effective thermoplastic created using three unique compounds. ABS is rigid, tough and impact resistant enabling effective use in a number of indoor and outdoor applications. Often recognized by its glossy surface or haircell texture, ABS possesses combination of properties making it an ideal choice in numerous industries.

ABS is exceptionally durable, has low moisture absorption, good dimensional stability, excellent chemical resistance, is very easy to fabricate, and thinner gauges can be die-cut. ABS also has a high heat tolerance which allows it to be thermoformed to shape, or sonic welded to various materials such as wood, epoxy, ceramic, and aluminum. ABS parts can also be fastened using screws, bolts, nuts, rivets, or spring steel fasteners.

Common Applications for ABS

The versatile properties of ABS combined with its ease of fabrication enables indoor and outdoor signage applications including:

Playgrounds

Wall Covering

Appliance Parts

Automotive Shrouds and Housings

Automotive Interior and Trim

Electrical Enclosures

Packaging Materials

Point of Sale Displays (POS)

Fabricated Parts

And more!

ABS Technical Data

| Property | Test Method | Value | Unit |

|---|---|---|---|

| Specific Gravity | D-792 | 1.04 | |

| Melt Flow | D-1238 | 1.7 | g/10 min |

| Gloss, 60° Angle | D-523 | 90 | % |

| Tensile @ Yield | D-638 | 5,100 | psi |

| Flexural Strength | D-790 | 8,000 | psi |

| Flexural Modulus | D-790 | 270,000 | psi |

| Notched Izod @ 73°F | D-256 | 6.3 | ft-lb/in |

| Notched Izod @ -40°F | D-256 | 2.2 | ft-lb/in |

| Rockwell Hardness | D-785 | 102 | R Scale |

| HDT @ 264 psi, Annealed | D-648 | 198 | °F |

| Vicat Softening Point | D-1525 | 224 | °F |

| Property | High | Average |

|---|---|---|

| Impact Strength | • | |

| Low Temp. Impact Strength | • | |

| Tensile Strength | • | |

| Flexural Modulus | • | |

| Heat Deflection Temp. | • |