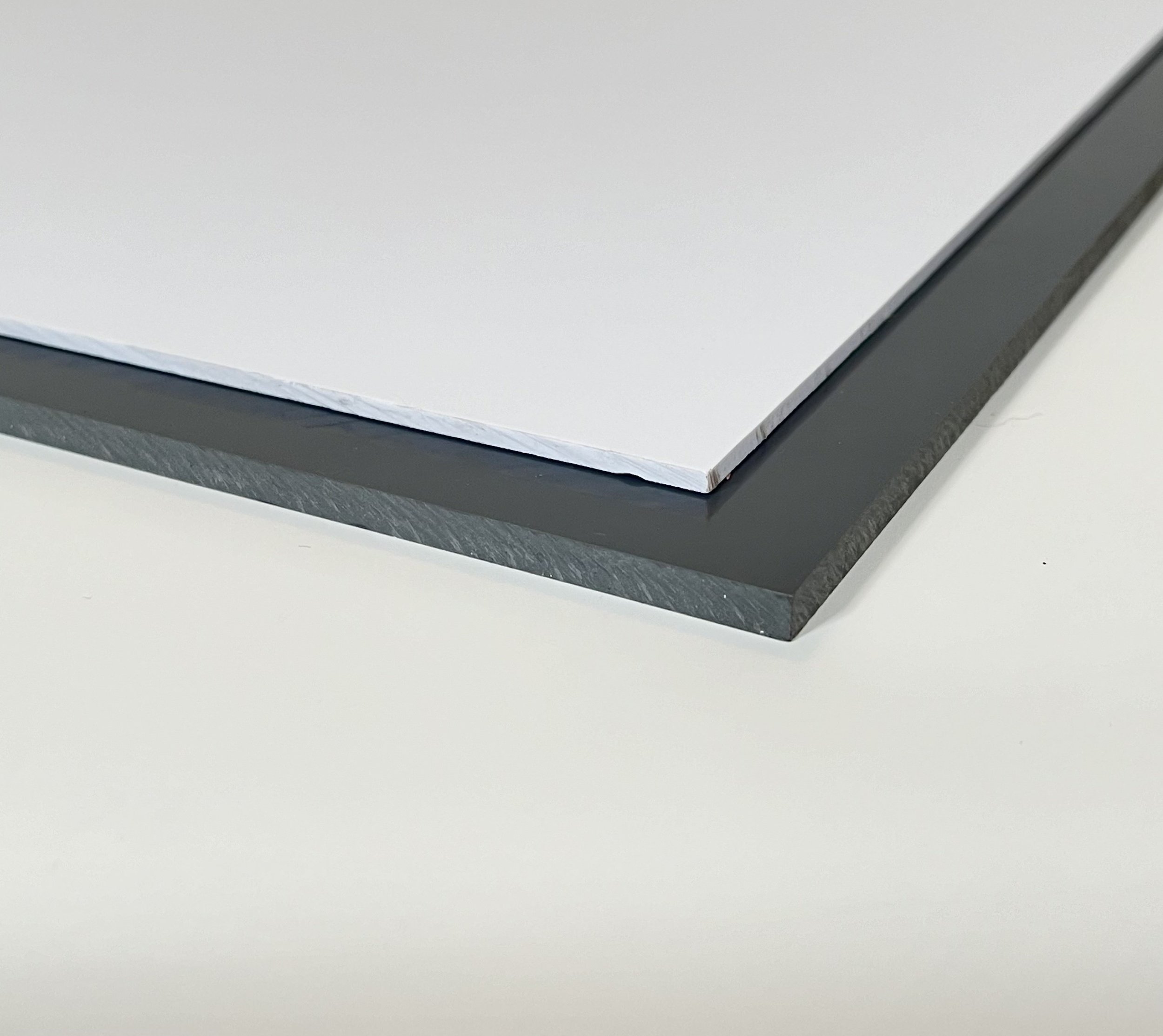

PVC Type 1

PVC Type 1 is a commonly used thermoplastic offering excellent corrosion, chemical and impact resistance. PVC is an economical and easily machinable material enabling a wide range of applications. PVC Type 1 is commonly used for corrosive-resistant valve and fittings but can also be used for pool components, lab equipment among other corrosive environments.

PVC Type 1 has numerous benefits including a higher heat distortion temperature, high strength to weight ratio, industry compliance (ASTM D-1784, ASTM E-84, and UL 94 V-0) and does not contain any plasticizers or fillers.

PVC Type 1 is a commonly used thermoplastic offering excellent corrosion, chemical and impact resistance. PVC is an economical and easily machinable material enabling a wide range of applications. PVC Type 1 is commonly used for corrosive-resistant valve and fittings but can also be used for pool components, lab equipment among other corrosive environments.

PVC Type 1 has numerous benefits including a higher heat distortion temperature, high strength to weight ratio, industry compliance (ASTM D-1784, ASTM E-84, and UL 94 V-0) and does not contain any plasticizers or fillers.

PVC Type 1 is a commonly used thermoplastic offering excellent corrosion, chemical and impact resistance. PVC is an economical and easily machinable material enabling a wide range of applications. PVC Type 1 is commonly used for corrosive-resistant valve and fittings but can also be used for pool components, lab equipment among other corrosive environments.

PVC Type 1 has numerous benefits including a higher heat distortion temperature, high strength to weight ratio, industry compliance (ASTM D-1784, ASTM E-84, and UL 94 V-0) and does not contain any plasticizers or fillers.

Common Applications for PVC Type 1

PVC Type 1s exceptional corrosion resistance is ideally suited for applications where maximum chemical defense is necessary, including:

Chemical Processing Equipment

Air Handling

Acid Baths

Fabricated Piping Components

Laboratory Workstations

Pool Components

Plating Tanks

Electrical Cabinets

Fabricated Parts

PVC Type 1 Technical Data

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Physical | |||

| Density | ASTM D-792 | g/cm3

| 1.42 |

|

| Water Absorption | ASTM D-570 | % | 0.06 |

| Rockwell Hardness | ASTM D-785 | R Scale | 115 |

| Shore Durometer | ASTM D-224 | D | 89 |

| Cell Class | ASTM D-1784 | 12454-B | |

| Mechanical | |||

| Tensile Modulus | ASTM D-638 | psi | 411,000 |

| Yield Strength | ASTM D-790 | psi | 7,500 |

| Flexural Modulus | ASTM D-790 | psi | 481,000 |

| Yield Strength | ASTM D-790 | psi | 12,800 |

| Izod Impact Strength | ASTM D-256 | ft-lb/in | 1.0 |

| Thermal | |||

| Vicat Softening Point | ASTM D-1525 | °C/°F | 83/181 |

| Heat Deflection Temp (66psi) | ASTM D-648 | °C/°F | 82/179 |

| Heat Deflection Temp (264psi) | ASTM D-648 | °C/°F | 80/176 |

| Coefficient of Linear Expansion | ASTM D-696 | in/in/°C | 5.8 x 10-5 |

| Coefficient of Linear Expansion | ASTM D-696 | in/in/°F | 3.2 x 10-5 |

| Flammability Ratings | |||

| Flame Spread Index | ASTM E-84 | 20 | |

| Flammability | UL 94V | 0 | |

| Flammability | ASTM D-635 | Self Extinguishing | |

| Chemical | |||

| Chemical Resistance | ASTM D-1784 | Class B | |

| Electrical | |||

| Electrical Volume Resistivity | ASTM D-257 | Ohm/cm | 5.4 x 1015 |

| Dielectric Constant | ASTM D-150 | 60 Hz | 3.9 |

| Dissipation Factor | ASTM D-150 | 60 Hz | 0.0096 |

| Loss Index | ASTM D-150 | 60 Hz | 0.030 |

| Dielectric Strength | ASTM D-149 | Volts / mil | 544 |