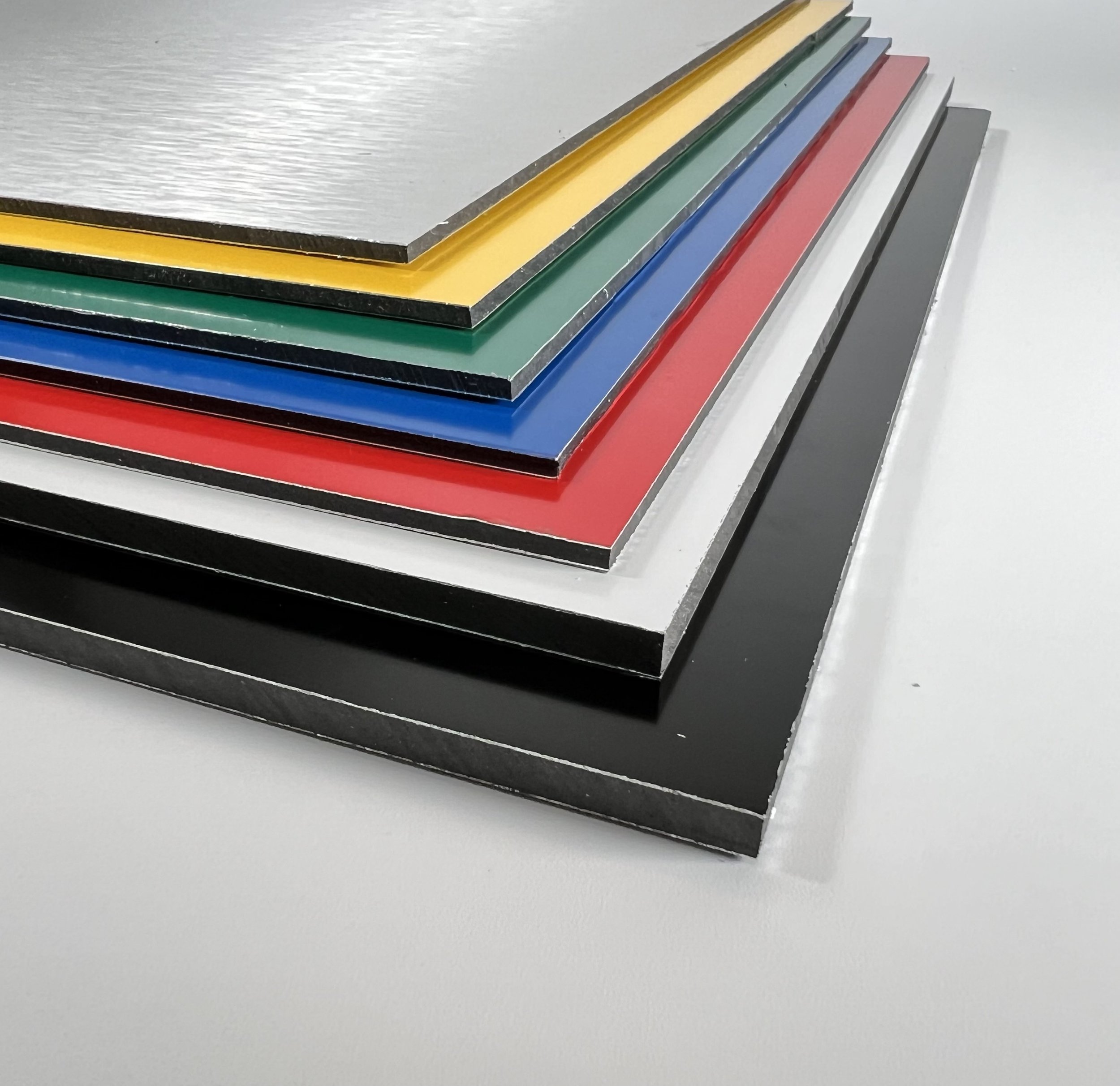

King® StarBoard®

King StarBoard is the original and leading marine-grade high-density polyethylene sheet. Starboard offers exceptional consistency and flatness through it’s proprietary manufacturing process. Starboard has a matte finish on both sides and is environmentally stabilized to withstand the harshest outdoor conditions.

King StarBoard never needs to be painted or refinished, works like wood, and is simply fabricated using common woodworking tools and techniques. These properties make StarBoard ideal for a variety of marine applications from replacing wood, to building boat components and furniture.

King StarBoard is the original and leading marine-grade high-density polyethylene sheet. Starboard offers exceptional consistency and flatness through it’s proprietary manufacturing process. Starboard has a matte finish on both sides and is environmentally stabilized to withstand the harshest outdoor conditions.

King StarBoard never needs to be painted or refinished, works like wood, and is simply fabricated using common woodworking tools and techniques. These properties make StarBoard ideal for a variety of marine applications from replacing wood, to building boat components and furniture.

King StarBoard is the original and leading marine-grade high-density polyethylene sheet. Starboard offers exceptional consistency and flatness through it’s proprietary manufacturing process. Starboard has a matte finish on both sides and is environmentally stabilized to withstand the harshest outdoor conditions.

King StarBoard never needs to be painted or refinished, works like wood, and is simply fabricated using common woodworking tools and techniques. These properties make StarBoard ideal for a variety of marine applications from replacing wood, to building boat components and furniture.

StarBoard Applications

Furniture

Bow Pulpits

Countertops

Frames and Trim

Grab Rails and Handles

Hatches and Doors

Rod and Cup Holders

Steps and Dock Boxes

Tray Tables

StarBoard Technical Data

| Properties | Units | ASTM | Nominal Values |

|---|---|---|---|

| Density | g/cc | D1505 | 0.955 |

| Tensile Strength @ Yield | psi | D638 | >4,100 |

| Tensile Modulus | psi | D638 | 255,000 |

| Elongation @ Break | % | D638 | >600 |

| Elongation @ Yield | % | D638 | 9.8 |

| Flexural Modulus | psi | D790 | 185,000 |

| Flexural Stress @ 5% Strain | psi | D790 | 3,810 |

| Compressive Properties 10% Strain | psi | D695 | 4,950 |

| Durometer | Shore D | D2240 | 68 |

| Tensile Impact | ft.lbs./in.2 | D1822 | 115 |

| Izod Impact Resistance | ft.lbs./in.2 | D256 | 1.1 |

| Brittleness Temp. | ºC (ºF) | D746 | <-76ºC (<-105ºF) |

| Vicat Softening Temp. | ºC (ºF) | D1525 | 128ºC ( 253ºF) |

| Heat Deflection Temp. 66 psi | ºC (ºF) | D648 | 99ºC (167ºF) |

| Screw and Nail Withdrawal | lbs | D1761 | 657 & 63 |

| Flammability | Rating | UL94 | HB |