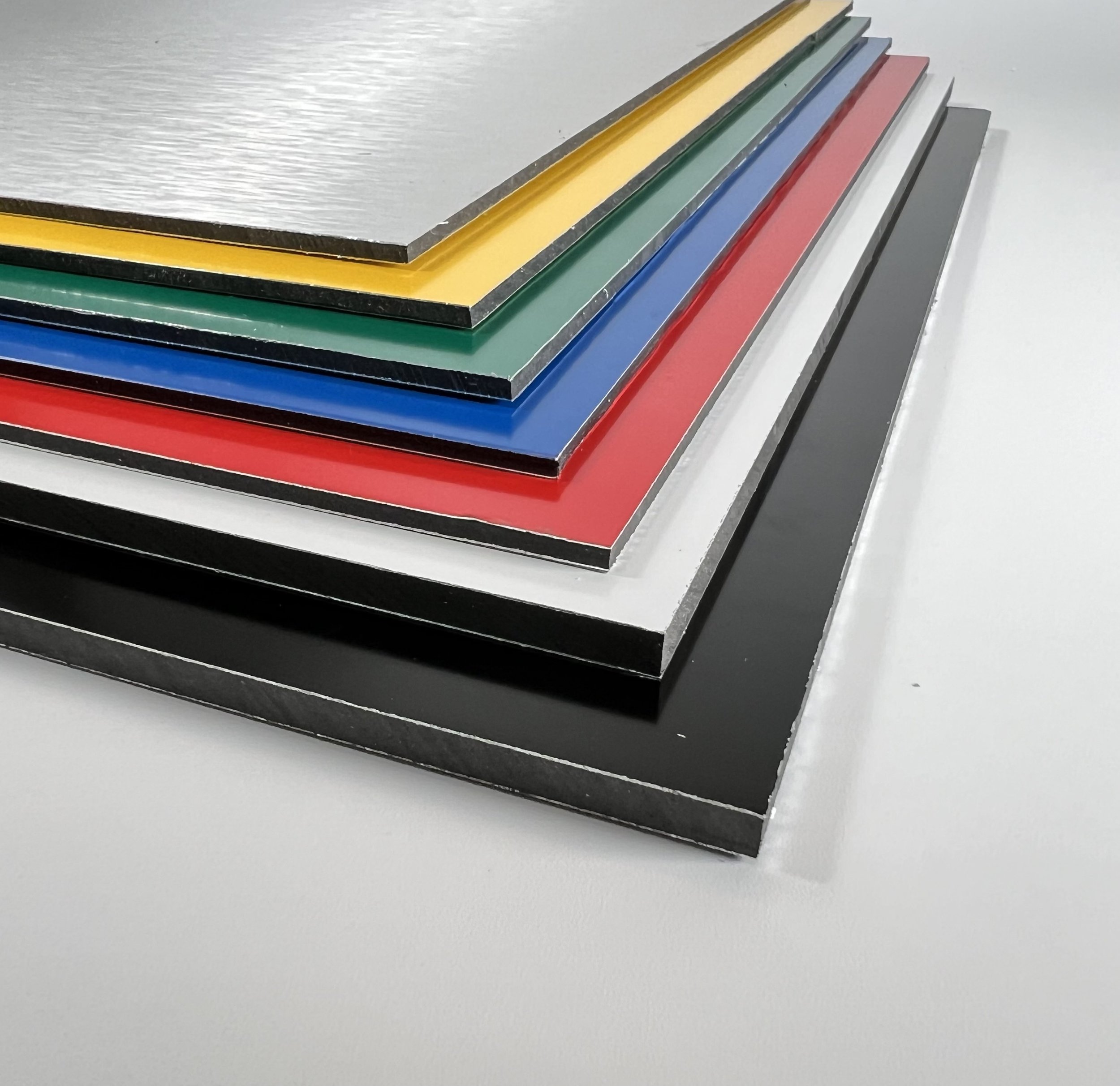

Aluminum Composite Panel

Aluminum composite (ACM, ACP) is a layered composite material comprised of a polyethylene (PE) core bonded between two thin layers of sign-grade aluminum. ACM is a lightweight option compared to sign-grade aluminum while its dimensional stability and durability make aluminum composite a great option for indoor and outdoor signage.

ACM is an extremely versatile material that can be easily cut, routed, grooved, bent, mounted, or installed using everyday tools. The PET-coated aluminum skin readily accepts traditional inks, paints, most digital inks, and PSA print media with minimal to no prep required.

Aluminum composite (ACM, ACP) is a layered composite material comprised of a polyethylene (PE) core bonded between two thin layers of sign-grade aluminum. ACM is a lightweight option compared to sign-grade aluminum while its dimensional stability and durability make aluminum composite a great option for indoor and outdoor signage.

ACM is an extremely versatile material that can be easily cut, routed, grooved, bent, mounted, or installed using everyday tools. The PET-coated aluminum skin readily accepts traditional inks, paints, most digital inks, and PSA print media with minimal to no prep required.

Aluminum composite (ACM, ACP) is a layered composite material comprised of a polyethylene (PE) core bonded between two thin layers of sign-grade aluminum. ACM is a lightweight option compared to sign-grade aluminum while its dimensional stability and durability make aluminum composite a great option for indoor and outdoor signage.

ACM is an extremely versatile material that can be easily cut, routed, grooved, bent, mounted, or installed using everyday tools. The PET-coated aluminum skin readily accepts traditional inks, paints, most digital inks, and PSA print media with minimal to no prep required.

Common Applications for ACM

The clean look of ACM combined with its ease of fabrication enables indoor and outdoor signage applications including:

Channel letter backs

POP displays

Digital printing

PSA mounting

ACM panels are also an excellent substrate as a canvas alternative for traditional oil painting. The thin gauge and rigid strength of ACM allow for easy storage of unused blanks and can eliminate the need for bulky stretcher bars and canvas storage. Its PET-coated surface requires little surface prep for painting with many traditional paints.

ACM Technical Data

| Physical Property | Standard | Units | 2MM (.080) | 3MM (.120) | 6MM (.240) |

|---|---|---|---|---|---|

| Aluminum Thickness | DIN 1784 | in. | 0.008 | 0.008 | 0.008 |

| Aluminum Thickness Deviation | DIN 1784 | in. | ±.0008 | ±.0008 | .0008 - .002 |

| Weight | - | lbs/ft² | 0.6 | 1 | 1.5 |

| Tolerance in Thickness | - | in. | ±.006 | ±.006 | ±.006 |

| Horizontal Flatness | DIN ISO 1101 | in. | 0.197 | 0.157 | 0.118 |

| Longitudinal Flatness | DIN ISO 1101 | in. | 0.315 | 0.197 | 0.197 |

| Techincal Property | Standard | Units | 2MM (.080) | 3MM (.120) | 6MM (.240) |

|---|---|---|---|---|---|

| Section Modulus W | DIN 53293 | in³/yds | 0.103 | 0.086 | 0.165 |

| Rigidity (Poisson's Ratio µ = .3) | DIN 53293 | kNm²/m | 0.97 | 0.14 | 0.86 |

| Modulus of Elasticity | EN 1999 1-1 | lbs/ft² | 10,153,660 | ||

| Aluminum Tensile Strength | EN 485-2 | lbs/ft² | ≥ 21,030 | ||

| 0.2% Stress Test | EN 485-2 | lbs/ft² | |||

| Elongation | EN 485-2 | % | 3 | ||

| Linear Thermal Expansion | EN 1999 1-1 | in/yd/ºF | 2.4 at 212 °F Temp difference | ||

| Temperature Range | - | °F | (-58°) - 176° | ||

| Physical Property | Standard | Units | Measurement (All Sizes) |

|---|---|---|---|

| Lacquering | - | - | Polyester |

| Coating Thickness | - | µm | ≥ 16 |

| Gloss (Initial Value) | ECCA T2 | % | 20 - 100 |

| Pencil Hardness | ECCA T2 | - | 2H |

*The nominal properties reported herein are typical of the product but do not reflect normal testing variance and therefore should not be used for specification purposes.