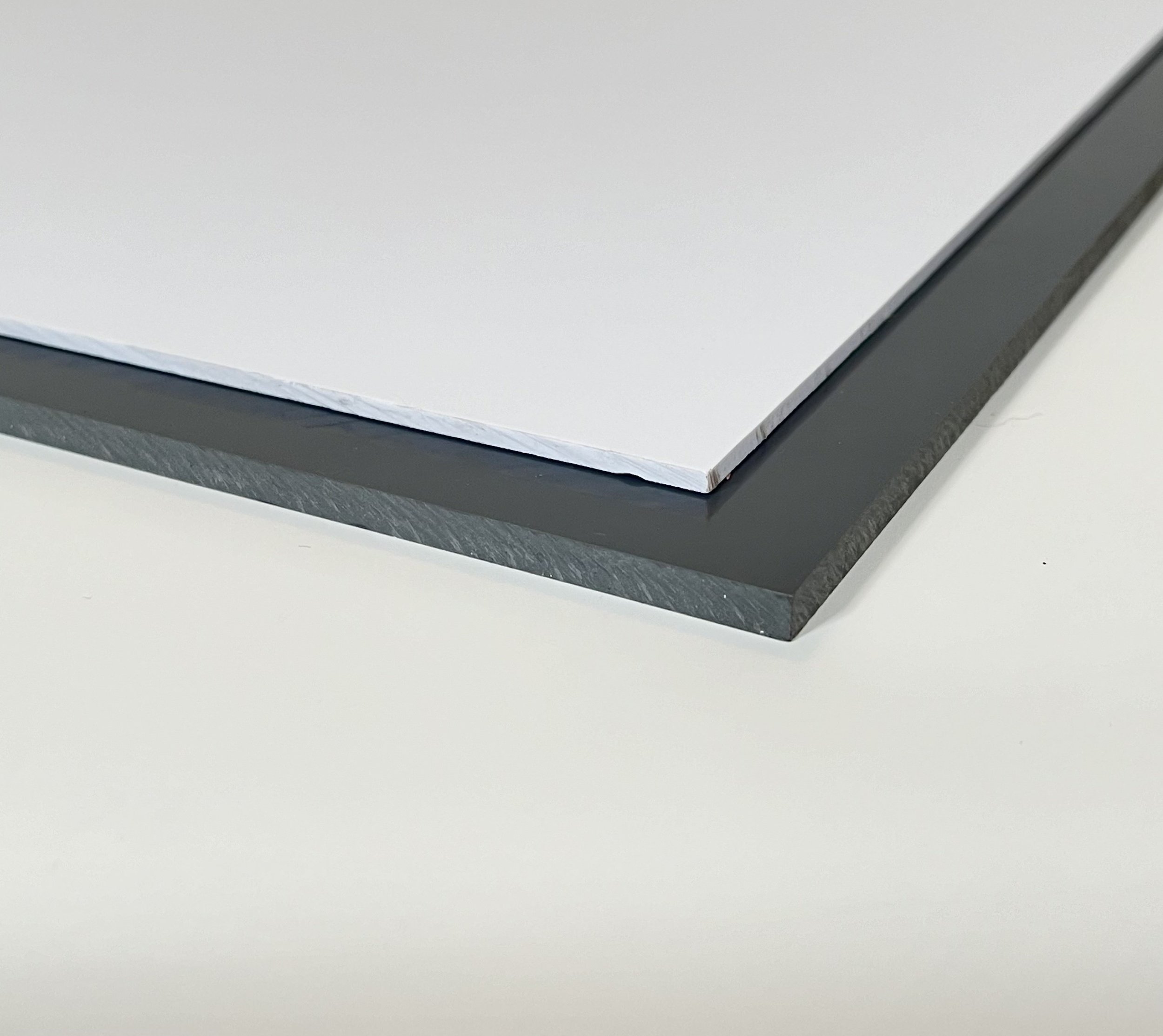

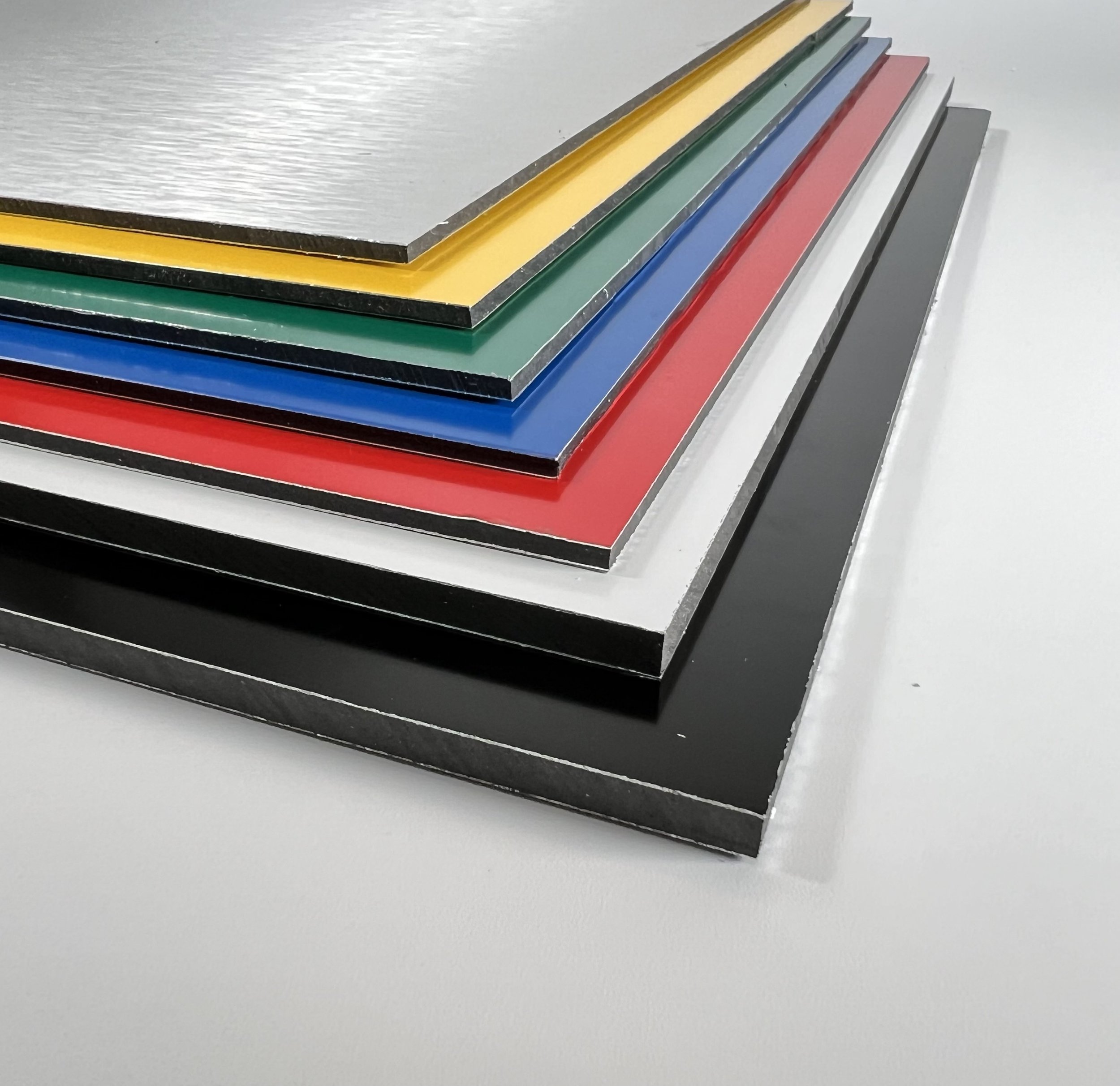

UHMW-PE

UHMW-PE sets the standard for engineering plastics and is a excellent general purpose material. With its unique combination of wear and corrosion resistance, low friction surface and impact strength, chemical resistance, moisture absorption, and high operating temperature UHMW retains key physical properties in a multitude of environments.

UHMW repro or “Reprocessed” is an economical and environmentally friendly option made from a virgin/recycled blend for non-food applications. UHMW repro retains its versatility with superior impact and chemical resistance; does not lose its durability, extremely low coefficient of friction or its inherent lubricity. UHMW excels in applications where high levels of friction are likely to occur.

UHMW-PE sets the standard for engineering plastics and is a excellent general purpose material. With its unique combination of wear and corrosion resistance, low friction surface and impact strength, chemical resistance, moisture absorption, and high operating temperature UHMW retains key physical properties in a multitude of environments.

UHMW repro or “Reprocessed” is an economical and environmentally friendly option made from a virgin/recycled blend for non-food applications. UHMW repro retains its versatility with superior impact and chemical resistance; does not lose its durability, extremely low coefficient of friction or its inherent lubricity. UHMW excels in applications where high levels of friction are likely to occur.

UHMW-PE sets the standard for engineering plastics and is a excellent general purpose material. With its unique combination of wear and corrosion resistance, low friction surface and impact strength, chemical resistance, moisture absorption, and high operating temperature UHMW retains key physical properties in a multitude of environments.

UHMW repro or “Reprocessed” is an economical and environmentally friendly option made from a virgin/recycled blend for non-food applications. UHMW repro retains its versatility with superior impact and chemical resistance; does not lose its durability, extremely low coefficient of friction or its inherent lubricity. UHMW excels in applications where high levels of friction are likely to occur.

Common Applications for UHMW-PE Repro

UHMWs combination of versatile properties and ease of fabrication enables numerous industrial applications including:

Augers

Bearings and Bushings

Chain Guides

Sprockets

Chute and Hopper Liners

Guide Rails and Rollers

Flights and Gears

Scraper and Plow Blades

Fabricated Parts

UHMW-PE Repro Technical Data

| Physical Properties | UHMW Repro | ||

|---|---|---|---|

| Property | Test Method | Units | Value |

| Density | ASTM D792 | gm/cm3

| .935 |

|

| Tensile Strength @ Yield 73° F |

ASTM D638 | psi | 3000 |

| Elongation @ 73° F | ASTM D638 | % | 290 |

| Relative Volumetric Abrasion Loss |

90 | ||

| Coefficient of Friction @ 73° F on Steel |

0.17 - 0.20 0.10 - 0.20 |

||

| Izod Impact Strength @ 73° F | ASTM D4020-96 | KJ/m2

| 96 |

|

| Hardness @ 73° F | ASTM D785 | D 63 - 69 | |

| Melting Point | ASTM D789 | °F | 275° - 280° |

| Coefficient of Linear Thermal Expansion |

ASTM D696 | 1/K | 1.9 x 104 |

| Continuous Service Temperature in air (max) |

°F | 180 | |

| Volume Resistivity | ASTM D257 | Ohm/cm | >1015 |

| Dielectric Constant (103 Hz) | ASTM D150 | ||

| Dielectric Strength | ASTM D149 | KV/mm | 900 |

| Specifications and Approvals | |||

| ASTM | D-4020 | UHMW-PE molding and extrusion materials | |

| FDA | Natural and Black UHMW Repro |

No | |

| Federal | L-P-390C | Plastic molding and extrusion material, polyethylene and copolymers (low, medium and high density) |

|

| Military | MIL-P-21922 | Plastic rods and tubes, polyethylene | |

| OSHA | UHMW-PE is not considered hazardous, as defined by OSHA Hazard Communications Standard 29 CFR 1910.1200 |

||