Image 1 of 19

Image 1 of 19

Image 2 of 19

Image 2 of 19

Image 3 of 19

Image 3 of 19

Image 4 of 19

Image 4 of 19

Image 5 of 19

Image 5 of 19

Image 6 of 19

Image 6 of 19

Image 7 of 19

Image 7 of 19

Image 8 of 19

Image 8 of 19

Image 9 of 19

Image 9 of 19

Image 10 of 19

Image 10 of 19

Image 11 of 19

Image 11 of 19

Image 12 of 19

Image 12 of 19

Image 13 of 19

Image 13 of 19

Image 14 of 19

Image 14 of 19

Image 15 of 19

Image 15 of 19

Image 16 of 19

Image 16 of 19

Image 17 of 19

Image 17 of 19

Image 18 of 19

Image 18 of 19

Image 19 of 19

Image 19 of 19

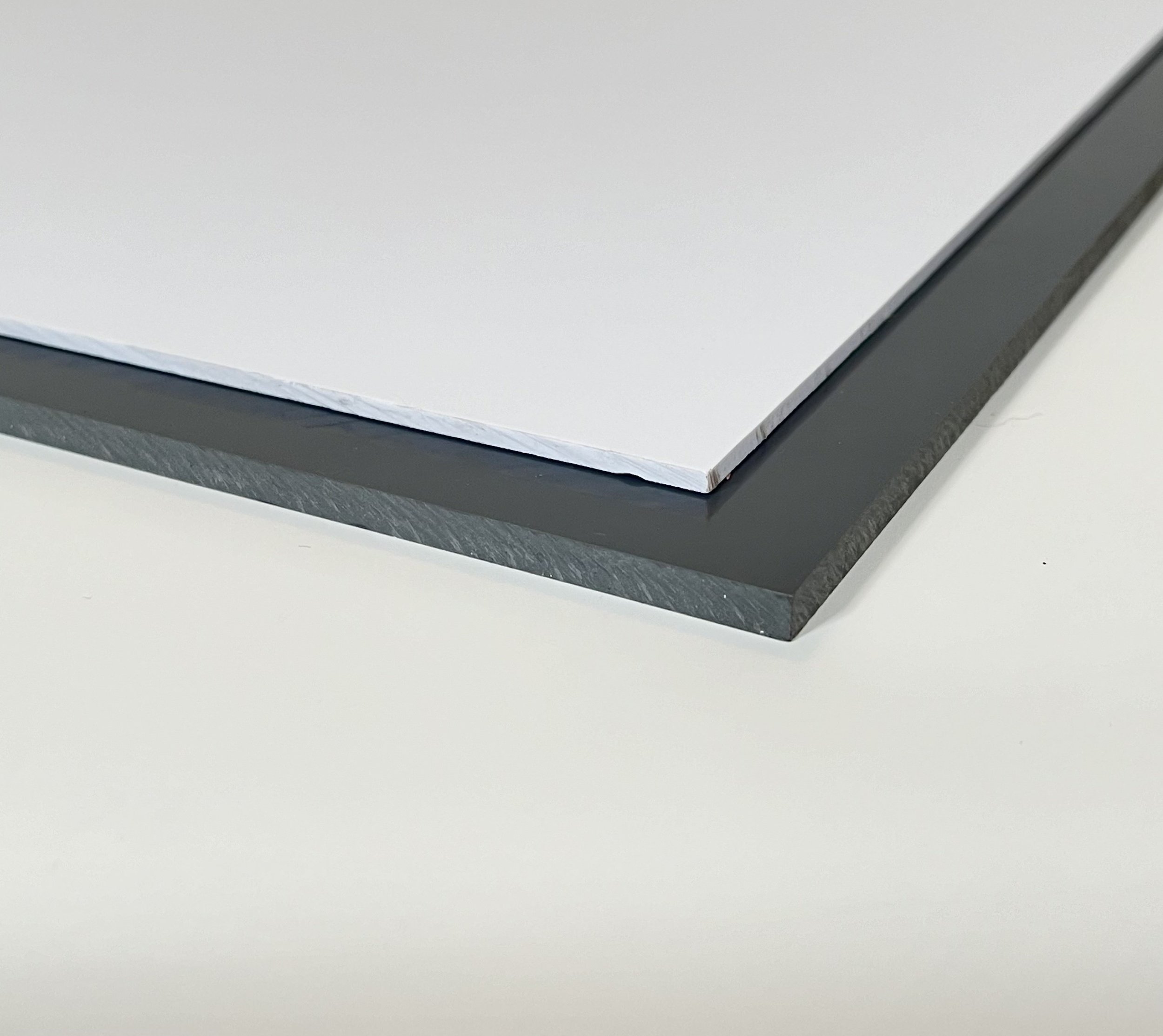

Cast Acrylic Mirror

Cast acrylic mirror is a lightweight, reflective thermoplastic material with a wide array of colors enabling utilization across a number of industries. Acrylic mirror is remarkably durable through it’s vacuum metalizing process in which the mirrored surface is created. The flashy mirror surface and inherent properties of cast acrylic enable many aesthetic applications including signage and POP displays.

Unlike traditional glass mirrors, cast acrylic mirror offers a lightweight and shatterproof alternative, reducing risks linked with breakage and fostering safer environments. The exceptionally light weight of acrylic mirror, being half that of comparable glass, reduces transportation costs and improves the installation process. In addition, acrylic mirror sheets can be mounted using screws or numerous suitable adhesives.

Cast acrylic mirror is a lightweight, reflective thermoplastic material with a wide array of colors enabling utilization across a number of industries. Acrylic mirror is remarkably durable through it’s vacuum metalizing process in which the mirrored surface is created. The flashy mirror surface and inherent properties of cast acrylic enable many aesthetic applications including signage and POP displays.

Unlike traditional glass mirrors, cast acrylic mirror offers a lightweight and shatterproof alternative, reducing risks linked with breakage and fostering safer environments. The exceptionally light weight of acrylic mirror, being half that of comparable glass, reduces transportation costs and improves the installation process. In addition, acrylic mirror sheets can be mounted using screws or numerous suitable adhesives.

Cast acrylic mirror is a lightweight, reflective thermoplastic material with a wide array of colors enabling utilization across a number of industries. Acrylic mirror is remarkably durable through it’s vacuum metalizing process in which the mirrored surface is created. The flashy mirror surface and inherent properties of cast acrylic enable many aesthetic applications including signage and POP displays.

Unlike traditional glass mirrors, cast acrylic mirror offers a lightweight and shatterproof alternative, reducing risks linked with breakage and fostering safer environments. The exceptionally light weight of acrylic mirror, being half that of comparable glass, reduces transportation costs and improves the installation process. In addition, acrylic mirror sheets can be mounted using screws or numerous suitable adhesives.

Cast Acrylic Mirror Applications

Schools

Gyms, Yoga, and Dance Studios

Hospitals

Retail Displays

Signage

Security

Theatre and Stage Setups

Prisons

Laser Engraving

Cast Acrylic Mirror Technical Data

| Physical | Test Method | Unit | Value |

|---|---|---|---|

| Specific Gravity/Relative Density | ASTM D792 | 1.19 | |

| Water Absorption | ASTM D570 | % | 0.4 |

| Mechanical | Test Method | Units | Value |

|---|---|---|---|

| Tensile Strength | ASTM D638 | psi | **11,030 |

| Tensile Modulus of Elasticity | ASTM D638 | psi | **490,000 |

| Flexural Strength | ASTM D790 | psi | **17,000 |

| Izod Impact Strength – Molded Notch | ASTM D256 | ft-lb/in Notch | **0.4 |

| Rockwell Hardness | ASTM D785 | **M-95 |

| Thermal | Test Method | Units | Value |

|---|---|---|---|

| Maximum Recommended Continuous Service Temperature | °F | 160 | |

| Softening Temperature | °F | 210-220 | |

| Melting Temperature | °F | 300-315 | |

| Deflection Temperature @ 264 psi (1.8 MPa) | ASTM D648 | °F | 203 |

| Deflection Temperature @ 66 psi (0.45 MPa) | ASTM D648 | °F | 207 |

| Coefficient of Thermal Expansion | ASTM D696 | in/in/°F | 3.0x10-5 |

| Flammability (Burning Rate) | ASTM D635 | in/minute | 1.019 |

| Smoke Density Rating | ASTM D2843 | % | 3.4 |

| Self-Ignition Temperature | ASTM D1929 | °F | 833 |