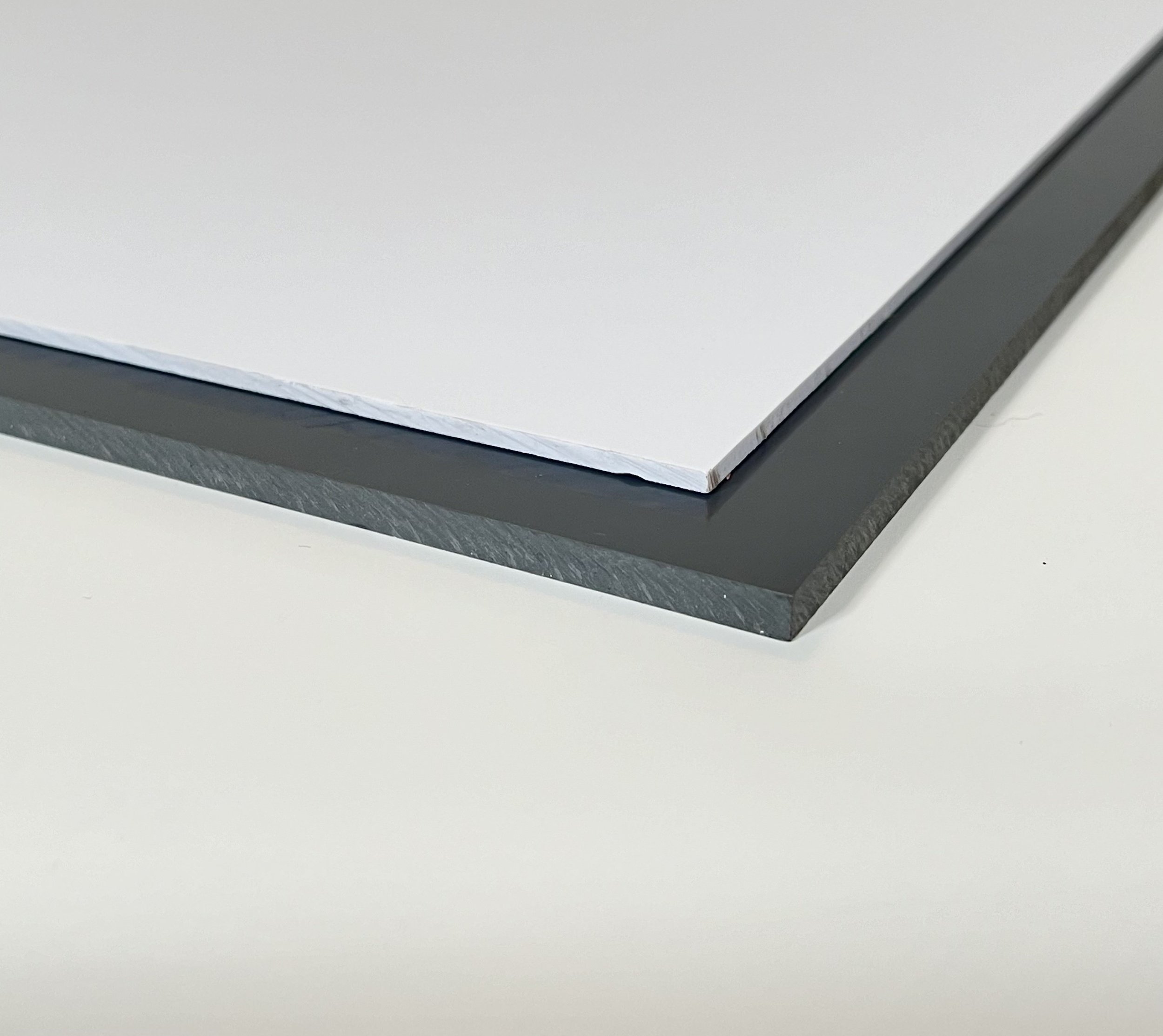

PTFE (Teflon) Sheet

PTFE is commonly referred to as Teflon® (a registered trademark of DuPont) and is a synthetic, nontoxic, fluorocarbon-based thermoplastic widely used in many industries. PTFE possesses a low coefficient of friction, superior electrical properties, high chemical resistance, and stability throughout a wide range of temperatures. These properties make PTFE and ideal choice for thermal and electrical applications such as high temperature seals and insulators.

PTFE is commonly referred to as Teflon® (a registered trademark of DuPont) and is a synthetic, nontoxic, fluorocarbon-based thermoplastic widely used in many industries. PTFE possesses a low coefficient of friction, superior electrical properties, high chemical resistance, and stability throughout a wide range of temperatures. These properties make PTFE and ideal choice for thermal and electrical applications such as high temperature seals and insulators.

PTFE is commonly referred to as Teflon® (a registered trademark of DuPont) and is a synthetic, nontoxic, fluorocarbon-based thermoplastic widely used in many industries. PTFE possesses a low coefficient of friction, superior electrical properties, high chemical resistance, and stability throughout a wide range of temperatures. These properties make PTFE and ideal choice for thermal and electrical applications such as high temperature seals and insulators.

PTFE Applications

Bearings and Bushings

Packaging and Conveying

Die Cutters

Food and Beverage

Chemical Processing

Gaskets and Seals

Machine Shops

Valves and Fittings

Oil and Gas

PTFE Technical Data

| Physical Property | Units | Test Method | Value |

|---|---|---|---|

| Tensile strength @ break @ 73°F | psi | D638 | 1,960 – 5,100 |

| Flexural modulus @ 73°F | psi | D790 | 50,000 – 90,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 3.5 |

| Coefficient of linear thermal expansion (CLTE) | (in/in F) | D696 | 4.8E-05 to 7.9E-5 |

| Coefficient of friction | D1894 | 0.0 46 – 0.2 | |

| Water absorption – 24 hours – 1/8″ thick | 0.036 – 0.11% | D570 | 0.0 – 0.01 |

| Deflection Temperature Under Load @ 264 psi | °F | D648 | 145 |